站點(diǎn)地圖

Product Description

With Industrial IoT 5G endorsement, and based on Renle's years of technology accumulation, the high voltage power modules realize full digitalization with the use of optical fiber multiplexing technology. The newly developed intelligent soft starters are equipped with standard industrial Ethernet and a variety of communication interfaces. Relying on industrial Ethernet, the soft starter realizes remote data analysis, remote software upgrade, remote debugging, remote virtual oscilloscope and other digital technologies.

□ Fiber multiplexing technology

□ Full digitalization of high voltage power modules

□ Different communication interfaces

□ Remote data analysis

□ Industrial Ethernet communication

□ Remote software upgrade

Data Visualization and Analysis

Real-time display of all data and running status

1. Soft starter is connected to the IT platform through the network protocol, and visualization of motor data is realized with IT technology;

2. Connection to the cloud server provides data for big data analysis and related artificial intelligence algorithms;

3. Full use of computing power of the cloud platform realizes online analysis and diagnosis of motor operation status, and realizes fault warning and optimal control.

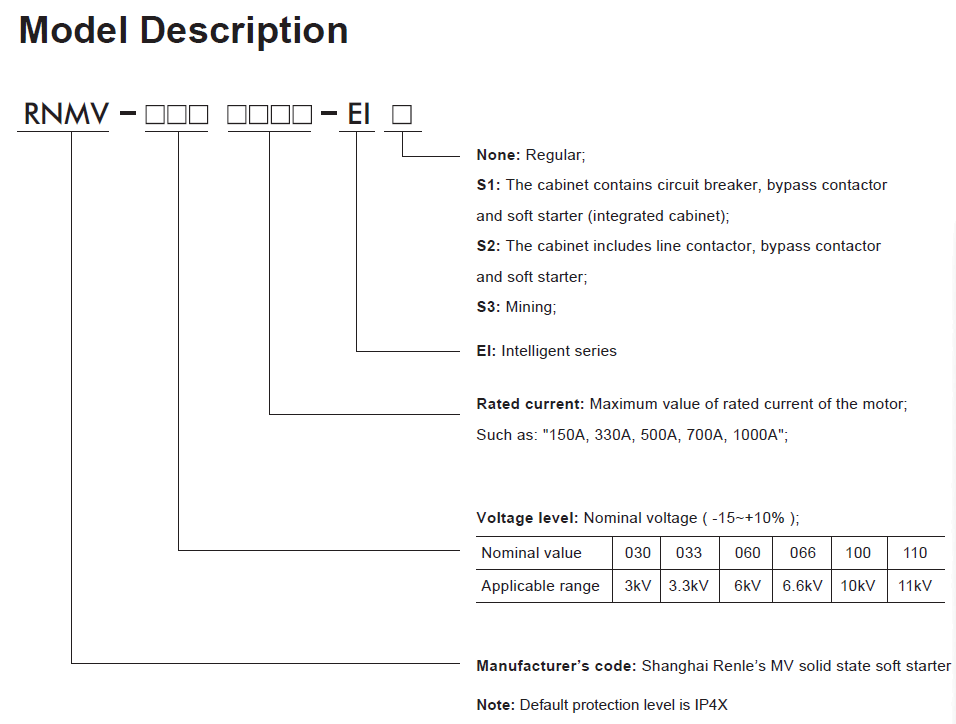

Product Model

standard

GB 311.1-1997《Insulation co-ordination for high voltage transmission and distribution equipment》

GB3906-2006《Alternating-current metal-enclosed switchgear and controlgear for rated voltages above 3.6kV and up to and including 40.5kV》

GB/T 13422-1992《Power semiconductor converters-Electrical test methods》

GB/T 3859.1-1993《Semiconductor convertors – Specifications of basic requirements》

GB/T 3859.2-1993《Semiconductor convertors – Application guide》

GB 4208-2008《Degrees of protection provided by enclosure (IP code)》

IEC-60298《AC metal-enclosed switchgear and controlgear for rated voltages above 1kV and up to and including 52kV》

IEC 60470《High-voltage alternating current contactors》

IEC 61000《Electromagnetic compatibility (EMC)》

JB/Z102《Technical conditions for high-voltage apparatus used in high altitude area》

GB/T 11022-1999《Common specifications for high-voltage switchgear and controlgear Standards》

Executed standards of high voltage soft starter controller for general type for mining

GB/T 12173-2008《Mining electrical apparatus for non-hazardous area》

JB/T 10251-2001《AC power & Electronic motor soft starters》

GB/T 3859.1-1993《Semiconductor converters-Specifications of basic requirements》

GB/T 3797-2005《Electrical control assemblies》

DL/T 593-2006《Common specifications for high-voltage switchgear and controlgear standards》

DL/T 404-2007《Alternating-current metal-enclosed switchgear and controlgear for rated voltages above 3.6kV and up to and including 40.5kV》

GB/T 14808-2001《High voltage alternating current contactors and contactor-Based Motor-starters》

GB 1207-2006《Inductive voltage transformers》

GB 1208-2006《Current Transformers》

Technical features

● Thyristor valve group series connection and dual power supply triggering technology is adopted;

● Optical fiber communication multiplexing technology is adopted for driving and data collection;

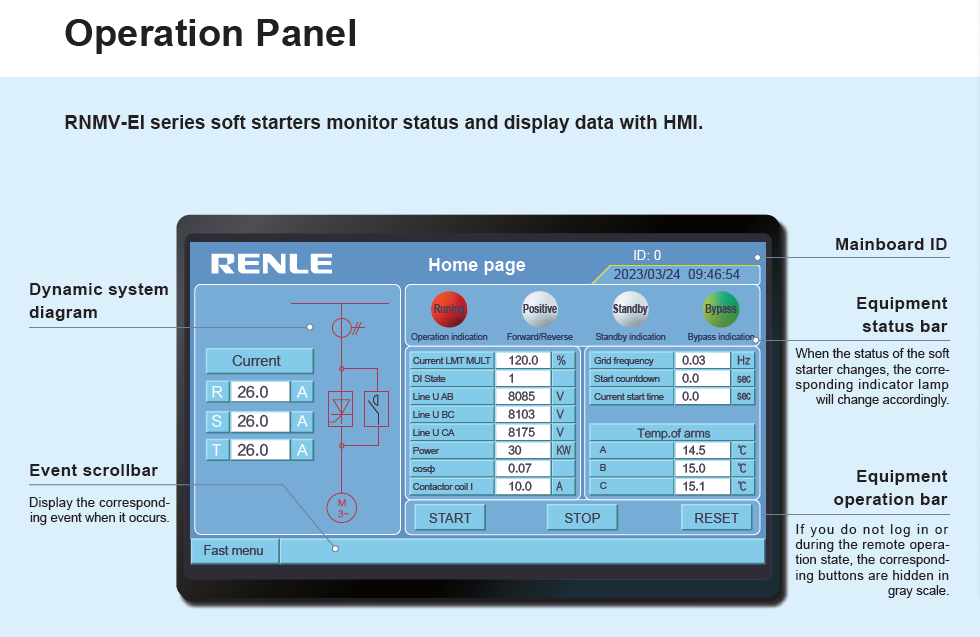

● Monitor and display system status and data in real time with HMI, and it is possible to modify and set the system parameters;

● Equipped with OBD and software dual overvoltage protection functions.

● Statistics of valve group limit data are performed after each startup to evaluate the system status;

● Synchronous use of phase-locked loop and three-phase conduction compensation technology control algorithm;

● Protections include: undervoltage, phase loss, overcurrent, overheating, thyristor overvoltage, triggering failure, abnormal voltage sharing, abnormal RC current, thyristor failure, optical fiber communication interruption, abnormal triggering power supply etc. Start of the soft starter is prohibited when identification is abnormal;

● Remote software update, commissioning, data waveform monitoring and fault analysis is realized through InterNet;

● After connecting to the cloud server through industrial Ethernet + 5G, the soft starter provides data for big data analysis and related AI algorithms, makes full use of the computing power of the cloud platform to realize online analysis and diagnosis of motor operating status, and realizes fault pre-warning and optimized control.

Soft Start Function

● Strong load adaptability, with 2 starting control modes:

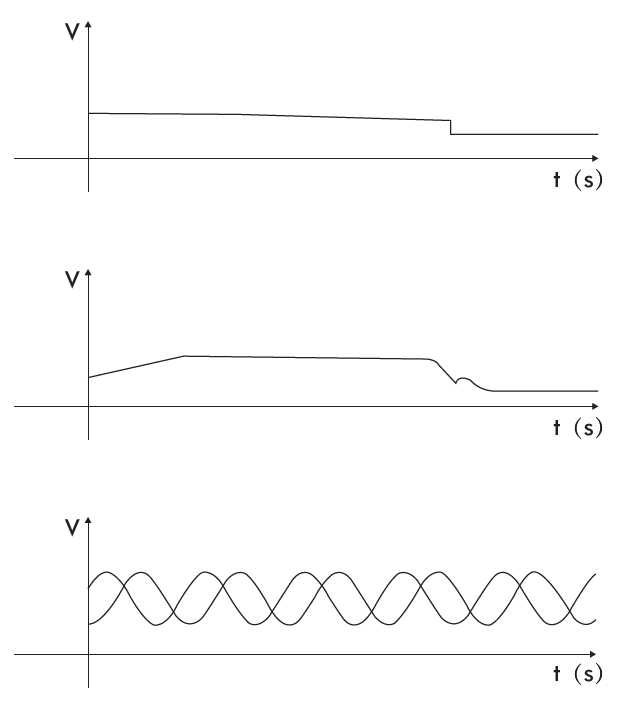

① Constant current mode: Nominal current of motor start is limited to the range of 100-500%.

② Voltage ramp mode: Control angle makes the output voltage linearly rise to the rated voltage.

● Free stop or soft stop is optional: Suitable for different stop occasions to meet special needs, such as to eliminate the water hammer effect of the water pump.

Support multiple communication protocols

1. Support ModBus RTU, ProfiBus-DP, TCP protocols;

2. Reservation of multiple interfaces facilitates parameter reading /writing and data monitoring;

3. Remote waveform monitoring and data analysis with the help of software;

4. Data download and software upgrade is performed with FTP and TFTP.